Operativity

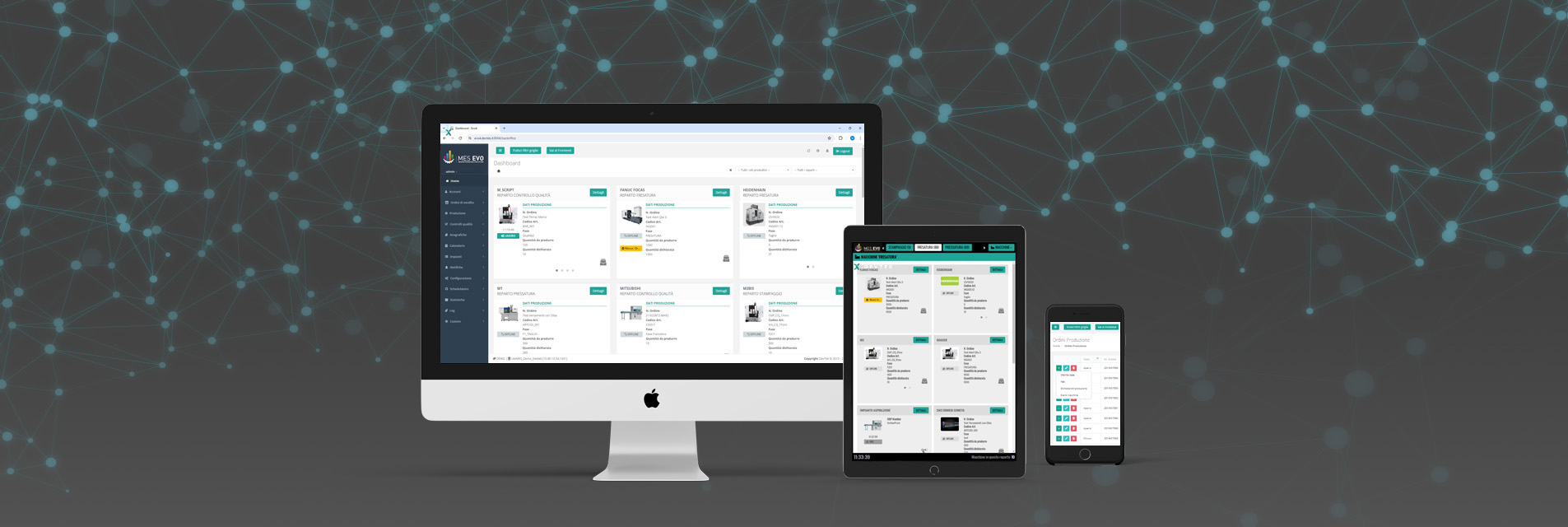

Backoffice

It allows system configuration, management of production orders and all related entities (items, cycles/phases, bills of materials...), monitoring of connected machine statuses, and production progress for individual interconnected or standalone work centers.

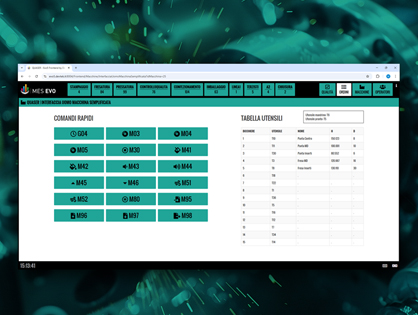

Frontend

It's the operational part of the software to be used on the shop floor via any browser-enabled device (PC, all-in-one, notebook, tablet). It allows operators to associate themselves with work centers by inputting setup times, maintenance, and production inputs, and to start, pause, and close work phases of production orders, also accessing all accompanying documentation (technical drawings, photos, videos, tool lists, work notes...).